Between two marble columns to the left of the V&A’s foyer hangs a giant sign, with PLYWOOD spelt out in bright red lettering. Below, a racing car is parked, being ogled like the McLarens at One Hyde Park. Inside the Porter Gallery, the walls glow red around a plywood set, while an aeroplane dangles from the ceiling. The effect is more blockbuster film than blockbuster exhibition. Does a material beloved of hipster-carpenters merit this star-treatment?

But then I watch the opening action sequence, and I get it. A group of us stand transfixed in front of one of the room’s many screens, watching a log being unravelled by a machine. It is a Douglas fir going through a rotary cutter to make veneers in British Columbia in 1954. Fixed to the wall behind is the result of such wizardry: a tall, undulating sheet of veneer, unfurled like a scroll.

The story of plywood – told here in chronological order, with extra detail provided by the co-curator Christopher Wilk’s surprisingly gripping book – has more plot developments and sudden changes of fortune than a 19th-century novel. It begins in ancient Egypt, where someone worked out that by stacking layers of veneer on top of each other, their grains going in opposite directions, you could make a material that was stronger than solid wood. A coffin made from panels of six-ply wood, joined together with wooden pegs, has been found in one of the pyramids.

Singer sewing machine with plywood box (1888). Victoria and Albert Museum

Having made this technological leap, civilisation promptly forgot about it, and the story of plywood picks up again only after the industrial revolution. There is a simple reason for this: before rotary-cutting, making veneers was an extremely fiddly and expensive business. Makers of high-end furniture started to experiment with glued veneers in the late 18th century, but it wasn’t until the second half of the 19th century, when thin veneers could be made swiftly and cheaply in a factory, that plywood came into its own.

Furniture makers raced to patent designs. Hanging from the ceiling is a doll’s chair, its seat and back made from a single sheet of perforated birch plywood. The innovative design was patented by William Gardner, an American, in 1873. A year later, another American called Isaac Cole patented a chair made entirely from plywood. This durable and flexible ‘new’ material also caught the eye of engineers: there is a drawing of a plywood pneumatic railway that was proposed for New York.

Just as things are looking up, our protagonist encounters a seemingly insurmountable obstacle: snobbery.

‘Mr and Mrs Veneering were bran-new people in a bran-new house in a bran-new quarter of London. Everything about the Veneerings was spick and span new. All their furniture was new […] And what was observable in the furniture, was observable in the Veneerings – the surface smelt a little too much of the workshop and was a trifle sticky.’

By the time Charles Dickens satirised the social-climbing nouveaux-riches in Our Mutual Friend, published in 1865, veneer already had a dodgy reputation. Handcut veneers had been fashionable before the industrial revolution, but the ease and low cost of producing machine-cut veneers meant that they started to be used as a way of disguising poor-quality furniture. A top layer of mahogany could give a hastily assembled pine cabinet a ‘veneer of respectability’.

The subtle distinction between good veneer and bad veneer was lost on consumers, who were content to buy plywood in the shape of hatboxes, sewing-machine stands, and tea chests. While he was in the Antarctic, Ernest Shackleton recycled some tea chests to bind his memoirs – Rudyard Kipling’s copy is on display here. Plywood was increasingly used in aeroplane construction: investment in research, especially during the First World War, led to developments in adhesives and moulding techniques, while the association with futuristic technology helped fix its image problem.

But despite tireless propaganda from the furniture industry in Britain and America, no one wanted to sit on a plywood chair until Alvar Aalto, the Finnish architect, moulded the seat of his Paimio armchair from birch plywood in 1930. Designers and the design-conscious middle classes went mad for the ‘revolutionary’ material and soon plywood chairs were selling out at Fortnum & Mason. In his book Homes Sweet Homes, published in 1939, Osbert Lancaster depicted a typical ‘Functionalist’ sitting room, with a pipe-smoking, spectacle-wearing New Statesman reader sitting on ‘mass-produced steel and plywood furniture’.

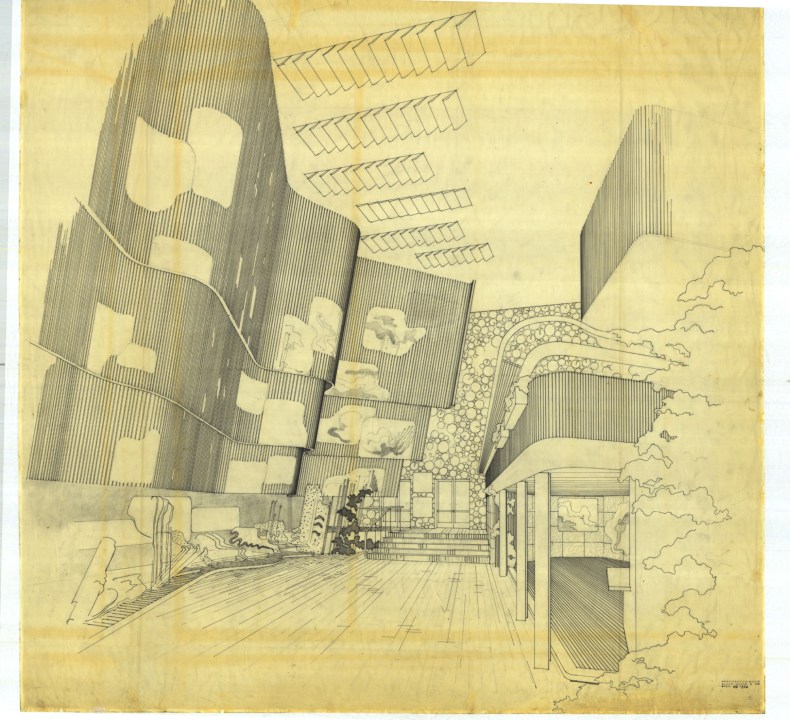

Drawing of Finnish Pavilion at the New York World’s Fair of 1939–40, designed by Alvar Aalto. © Alvar Aalto Museum

The material’s intrinsic qualities meant it was popular with builders and architects, who used it both structurally and sculpturally. Inside a full-scale reproduction of half a plywood house, designed in 1936, is a collection of photographs and documents that shows how plywood was used in building projects. Alongside diagrams of prefabs, there’s a wonderful sketch of the Finnish Pavilion at the World’s Fair in New York in 1939, for which Aalto and his wife used plywood to create a wavy, triple-decker wall. In the V&A’s Madejski garden are some modern skating shelters from Canada, which follow in the same tradition.

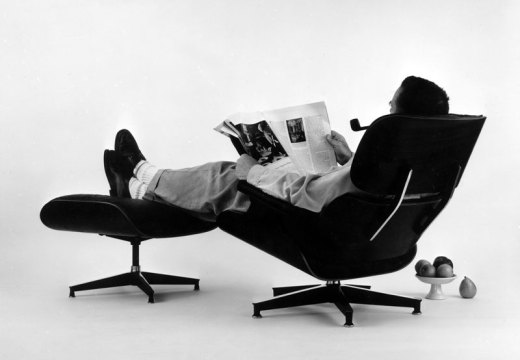

Despite the growing interest in plywood before the Second World War, it wasn’t manufactured on a large scale until after 1945. Wilk’s narrative emphasises the role the war played in changing the status of plywood. Allied governments pumped money into developing plywood as a metal substitute for use in boats and planes, which led to dull but important improvements, again in moulding and gluing. Geoffrey de Havilland’s plywood Mosquito bomber was the most directly successful outcome; the most indirectly successful was Charles and Ray Eames’s DCM chair. The couple had honed their moulding skills during the war, when they were charged with producing thousands of plywood leg splints for injured sailors in the American navy. Mid-century-modern geeks are well catered for in this show, with several beautiful specimens to lust over. I rather liked the 1950s Japanese ‘butterfly’ stool, made from rosewood veneer.

British de Havilland Mosquito (1941). Photo: © de Havilland Aircraft Museum

The post-war DIY boom was good news for plywood, which was simple for amateurs to get hold of and experiment with. You get the sense from the exhibition’s magazine covers and films (there’s a funny one of a 1950s housewife daintily helping her husband erect some shelving) that the entire middle class in Britain and America was building its own surfboards and sailing in plywood boats. The public, it seemed, had finally fallen in love with a once-unlovable material. But then, catatrophe! On to the scene came new forms of composite wood: MDF, chipboard, and OSB. Flimsy but cheap, these young pretenders usurped plywood as the default option for builders and DIYers.

Two decades into the 21st century, however, and plywood’s future is looking bright again. The ubiquitous Scandi aesthetic has led to a demand for light-coloured, ‘natural’-looking wood products. Positive vibes also come from plywood’s continued association with new technology – in this case, advances in digital manufacturing, where a computer feeds a pattern to a cutting machine. The curators have chosen to feature the ‘Evie’ stool from OpenDesk, which produces and compiles open-source furniture designs. The idea behind the project – giving local craftsmen control over the means of production – is laudable, but the end result, as well as being expensive to make, looks unsophisticated next to the gorgeous mid-century chairs.

After examining the thorny question of sustainability – the regulation around plywood production is tightening, but there’s still some way to go – the exhibition ends on a cliffhanger. Some people in Austria have worked out that if you cut plywood in a kind of net pattern, you can bend it and shape it any way you want it. All we need is a latter-day Aalto or Eames to realise the full potential of this development, and the sequel to Plywood: the movie could soon be coming to a living room near you.

‘Plywood: Material of the Modern World’ is at the Victoria and Albert Museum, London, until 12 November.

Unlimited access from just $16 every 3 months

Subscribe to get unlimited and exclusive access to the top art stories, interviews and exhibition reviews.

![Masterpiece [Re]discovery 2022. Photo: Ben Fisher Photography, courtesy of Masterpiece London](http://www.apollo-magazine.com/wp-content/uploads/2022/07/MPL2022_4263.jpg)

It’s time for the government of London to return to its rightful home